The Business of Silver with Mercury: A Comprehensive Guide

Silver with mercury has long been a topic of interest in various industries, particularly in the realm of mining and manufacturing. Understanding how these two elements interact and their applications can significantly enhance business practices and product development.

The Chemistry of Silver with Mercury

The unique properties of silver and mercury make their combination particularly valuable in a variety of industrial applications. Silver is a highly conductive metal, while mercury in its liquid form is effective at amalgamating with other metals. This amalgamation process typically results in a product that retains the conductivity of silver and the unique liquid properties of mercury.

Understanding Amalgamation

Amalgamation refers to the process of combining mercury with metals to form a new substance. When silver is mixed with mercury, it forms an amalgam that is used for a variety of purposes. This process has been utilized for centuries, especially in mining, where it is used to extract gold and other precious metals.

The Role of Liquid Mercury in Businesses

- Mining Industry: In the mining sector, liquid mercury plays a vital role in the extraction of gold, allowing for more efficient recovery rates.

- Manufacturing: Silver-mercury amalgams are employed in the creation of high-quality electrical contacts and devices due to their excellent conductivity.

- Dental Applications: The dental industry has utilized silver amalgam fillings for decades due to their durability and ability to withstand dental pressure.

- Artisanal Crafts: Artisans use silver with mercury in various crafting applications, enhancing the aesthetic properties of their work.

Benefits of Using Silver with Mercury

The benefits of utilizing silver with mercury in business extend beyond mere application. These benefits can lead to increased profitability and operational efficiency. Here are some key advantages:

Enhanced Efficiency in Gold Extraction

Companies involved in gold mining can significantly increase their yield by using silver with mercury. The amalgamation process allows for the effective separation of gold from ore, leading to higher recovery rates and lower processing costs. This efficiency not only saves time but also reduces the environmental impact associated with mining practices.

Improved Electrical Conductivity

In manufacturing, the use of silver-mercury amalgams can result in superior electrical conductivity, which is crucial in the production of electrical equipment. This enhanced performance leads to better-performing products, appealing to both consumers and industry professionals.

Durability in Dental Solutions

Dental amalgams containing silver are known for their strength and durability. They can withstand the test of time and provide long-lasting solutions for patients. The reliability of these amalgams ensures that dental professionals can focus on providing the best care without worrying about frequent replacements.

The Risks and Mitigation Strategies

While there are numerous benefits to using silver with mercury, it is also essential to recognize the associated risks. Mercury is toxic, and its improper handling can lead to serious health and environmental concerns.

Health Risks Associated with Mercury

Exposure to mercury can have detrimental effects on human health, including neurological damage and respiratory issues. As a result, companies must implement strict safety protocols when working with liquid mercury.

Environmental Considerations

The environmental footprint of mercury use is significant. Contamination of freshwater sources and risk to wildlife are critical concerns. Businesses must adhere to local regulations and best practices to minimize their environmental impact.

Best Practices for Safe Handling

- Training: Ensure all employees are well-trained in the safe handling and disposal of mercury.

- Personal Protective Equipment: Implement the use of appropriate PPE to minimize exposure risks.

- Monitoring: Regular monitoring of mercury levels in the workplace is necessary to ensure safety and compliance.

- Proper Disposal: Utilize certified disposal methods for any mercury waste to prevent environmental contamination.

Applications of Liquid Mercury and Silver in Various Industries

The amalgamation of silver with mercury has found its way into multiple industries, showcasing its versatility. Here’s a deeper look into specific applications:

Mining and Metallurgy

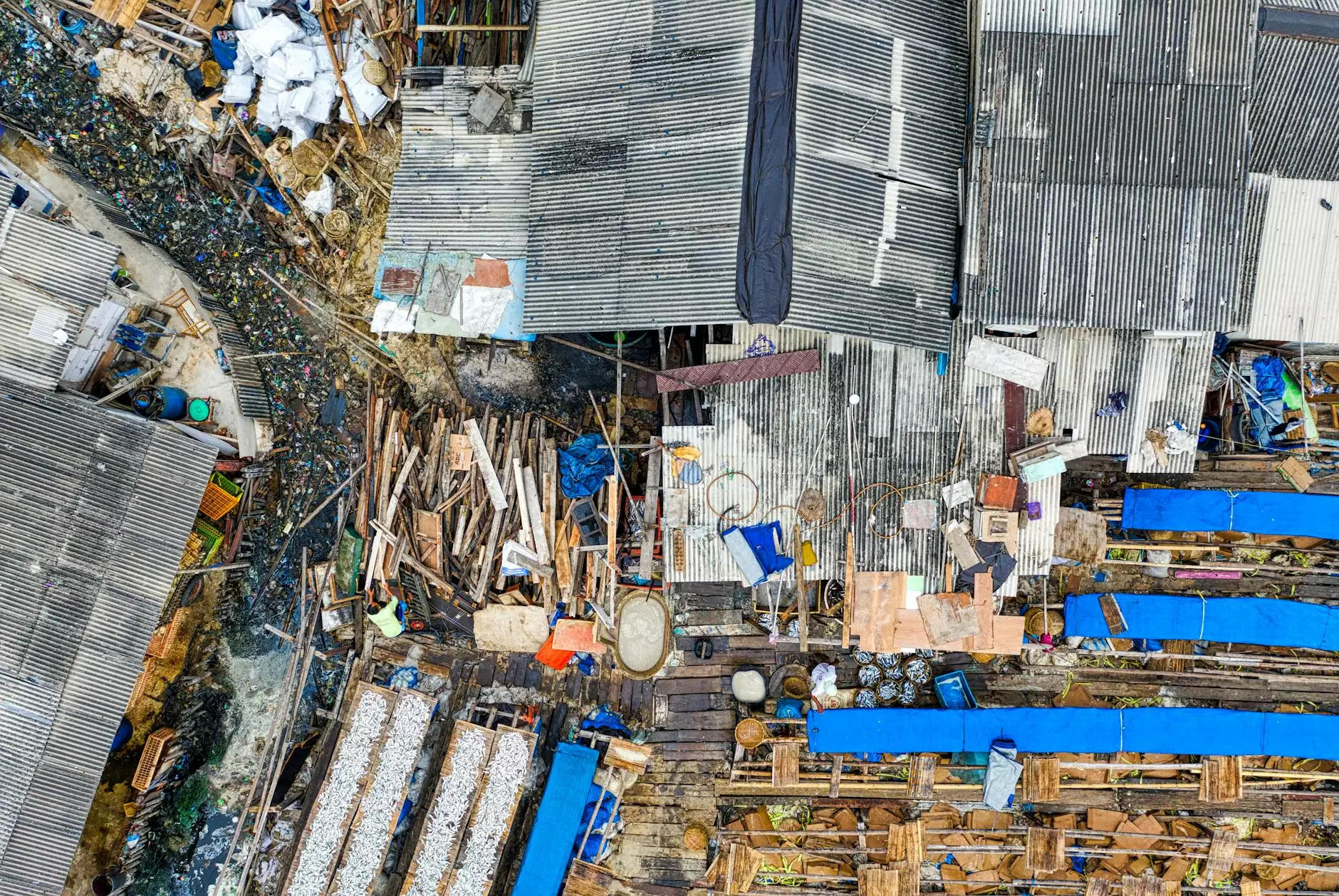

In mining, silver with mercury is primarily used for gold extraction due to its ability to form an amalgam. This technique allows miners to recover gold from ore more efficiently. Many miners in artisanal and small-scale mining settings rely on this method due to its cost-effectiveness.

Electronics and Electrical Manufacturing

The combination of silver and mercury creates an amalgam that has excellent conductivity, making it an ideal solution for various electronic components. From switches to circuit boards, the application of silver with mercury can be seen in multiple electrical devices, ensuring a reliable performance.

Dentistry

The dental industry has employed silver-mercury amalgams in restorative dentistry for over a century. Despite the rise of composite materials, silver amalgams remain a prominent choice due to their longevity and resistance to wear.

Cultural and Artistic Uses

Artists have utilized the properties of silver with mercury in traditional crafts, including inlaid jewelry and intricate designs. The lustrous finish achieved through these processes highlights the aesthetic appeal and uniqueness of artisan work.

Conclusion: The Future of Silver with Mercury in Business

The integration of silver with mercury into various industries presents both opportunities and challenges. As technology advances and regulations tighten, the methods and applications of these materials will continue to evolve. Businesses that focus on innovation and safety will likely emerge as leaders in their respective sectors, paving the way for new practices that harness the benefits of this unique amalgam.

In the coming years, as the demand for sustainable and efficient solutions grows, industries must adapt and explore alternative ways to utilize silver and mercury responsibly and effectively. With careful consideration of both the benefits and risks, businesses can leverage silver with mercury to enhance their operations while prioritizing safety and environmental stewardship. Businesses interested in procuring high-quality liquid mercury should consider reputable suppliers such as DS Chemek for their needs.

Take Action Today!

Embrace the potential of silver with mercury in your own business. Whether you are in mining, manufacturing, or the health sector, understanding and effectively using these materials can significantly impact your success. Stay informed, prioritize safety, and strive for excellence in every aspect of your operations.